Focusrite Audio Engineering Ltd. has been around for so long,

it’s easy to forget how many great products they’ve made over the years. We recently had a chance to sit down with the guiding lights of the company, Phil Dudderidge (Executive Chairman) and Rob Jenkins (Director of Product).

Phil, your background is in live sound, right?

PD: Yes. I started, aged 18, as a roadie driving bands. One day I had the opportunity to go for a job doing front-of-house, which I’d never done in my life, with Led Zeppelin. I was 21, and when you’re 21, you can do anything! So I said, “Yeah, I can do that.” That was my entré into live sound. It involved a European tour, followed by a US tour in the spring of 1970. We came out to the States and did 26 shows in about a month, which was a real killer. As soon as we finished one, we’d pack the truck and move on to the next, with the complement of three road crews. It was an arena tour, treated like a club tour. The only thing we didn’t have to do was put up the main PA system. That was provided by the local company that had been contracted by the promoter at each venue. We used our British [Watkins Electric Music (WEM)] PA system we brought over with us as monitors, because back then no one had come up with a solution for monitoring. Big sidefill [monitors] were on either side of the stage. It was a great education – it convinced me, at the tender age of 21, that I didn’t really want to spend my life touring. However, I got really turned on by the PA systems that I came across. We were using different systems around the country from some companies that have disappeared, but also from some very notable ones, like Showco and Clair Brothers. I saw a lot of different ways of doing the same job with the equipment that was available at the time. The state of the live sound industry, at that time, was in a place where everything was still there to be invented. They were repurposing speaker systems designed for movie theaters, rather than systems that had been designed for concert tours. The one system that really stood out in my mind was a John Meyer design that was supplied by McCune [Sound Service] at The Forum in L.A., which was the only flying system on the whole tour – it was completely revolutionary. When I went back to England, I didn’t want to keep touring, in general, and with Zeppelin in particular.

Why Not?

PD: It was really hard work. The band was great, both as musicians and also as guys. But within the management there was a complete lack of any consideration for the crew. It was like, “If I carry on doing this, I’ll be dead.” So I started working in the industry. Initially I got a job with Hiwatt [guitar amp builders], which wasn’t the best choice, but they wanted to get into PA systems and I knew the owner. I worked with them for a year, running a Hiwatt PA system for both demonstration purposes and also as a rental system, doing small festivals and concerts, as well as gaining more experience.

That was front of house?

PD: Yes, and everything else. I did that for about a year, and then started a company with a friend of mine building PA systems. After about a year and a half, one of my two partners [Graham Blyth] and I split away to start Soundcraft, in order to concentrate on building mixing consoles. That led to a 15-year history with that company before we sold it to Harman in 1988. With Soundcraft, I was very involved in running the business, running sales and marketing, and building an international distribution network. I developed my skills as a marketer; I was very brand focused. I think that was something that a lot of people didn’t quite appreciate, the value and importance of brands back then. They were much more focused on just making equipment. I had the arrogance, with hindsight, when we were starting Soundcraft, to think that one day Soundcraft could be to mixers what JBL were to speakers. It’s probably no coincidence that we ended up selling the company to Harman. It kind of came together that they ended up distributing Soundcraft in the U.S. before they bought the company. That takes us to 1989, when I had the opportunity to buy Focusrite, which had been started by Rupert Neve [Tape Op #26, #87]. They had gotten into financial difficulties; I had the opportunity to buy it out of insolvency and restart the business.

Rupert Neve started it, and then you came in?

PD: Yes. By the time I acquired the assets, the company was closed and I had to restart it. So I acquired the brand, the design assets, and so on.

Did Rupert stay on?

PD: No. He didn’t want to join the new company. I think he was feeling too burned out by the experience. But he did help us a lot in the transition. We initially hired a number of previous employees as consultants to help us get up to speed, but because we were in a different part of the country, we had to basically build a new team. Rob Jenkins joined the company at that time. By then I was 40 years old, and a much more mature businessperson. I approached running Focusrite with perhaps less emotion and more business savvy than I had previously. As businesses grow they have new problems and issues. My role has been as much an enabler of people like Rob to actually deliver the goods, in terms of the products and the way we bring them to market, the marketing of the products, and so on. We have an amazing team of people. I try not to take too much credit, because it’s they who really deliver everything that the brands represent.

Initially Focusrite was building consoles?

Well, that’s what the company was most noted for.

The Focusrite ISA consoles. There’s that great documentary, The Story of the Focusrite Studio Console.

PD: Yeah, but the old company had already been selling some outboard channels in 8-module and 4-module racks. These vertical modules were the mic pre and EQ modules, the ISA 110, which we then used as the fundamental building block for a second generation of Focusrite consoles, as well as the ISA 130 Dynamic Processor module.

How did you get the company back on its feet?

PD: We focused initially on producing some cash flow. We were making the outboard equipment that Rupert had developed, but our real energy was going into developing the new Focusrite Studio Console. Unfortunately, with hindsight, our timing was really wrong. There was a general recession, our console prices were too high for studios, and there was concurrently a big recession in the recording industry, particularly in the early ‘90s. Neve and SSL were duking it out, and we just couldn’t compete. We decided in ‘92 to get out of the console business. I like to say we were the last in, and the first out of, the large format console business. What we decided to do, rather than just close the doors, was to reinvent the business as an outboard company. The original Red Range was part of that strategy. We introduced that in ‘93.

You were one of the first companies to

do that. There weren’t many outboard mic pres, EQs, or compressors back then.

PD: Well, the original plan was to replace everything we had already been doing with the new Red Range. We actually found that there was demand for both the original ISAs and the Reds. The industrial design of the Red Range was so radical and beautiful that a lot of people wanted to buy the product before they even knew what it did. Then, when people found out it was actually the original mic pre circuitry that Rupert developed, and the same EQ and so on repackaged, that gave them a lot of confidence. We ran both the original ISA products that had blue and gray front panels alongside the new Red Range, which initially was a four-channel mic pre [Red 1], a two-channel EQ [Red 2], and a two-channel compressor [Red 3]. And then we had the single channel Red 6 [mic pre and EQ] and the Red 7, which was a mic pre with compressor and de-esser.

I have one of the Red EQs, and it’s never needed service of any kind. At about this point, Rob Jenkins enters the picture?

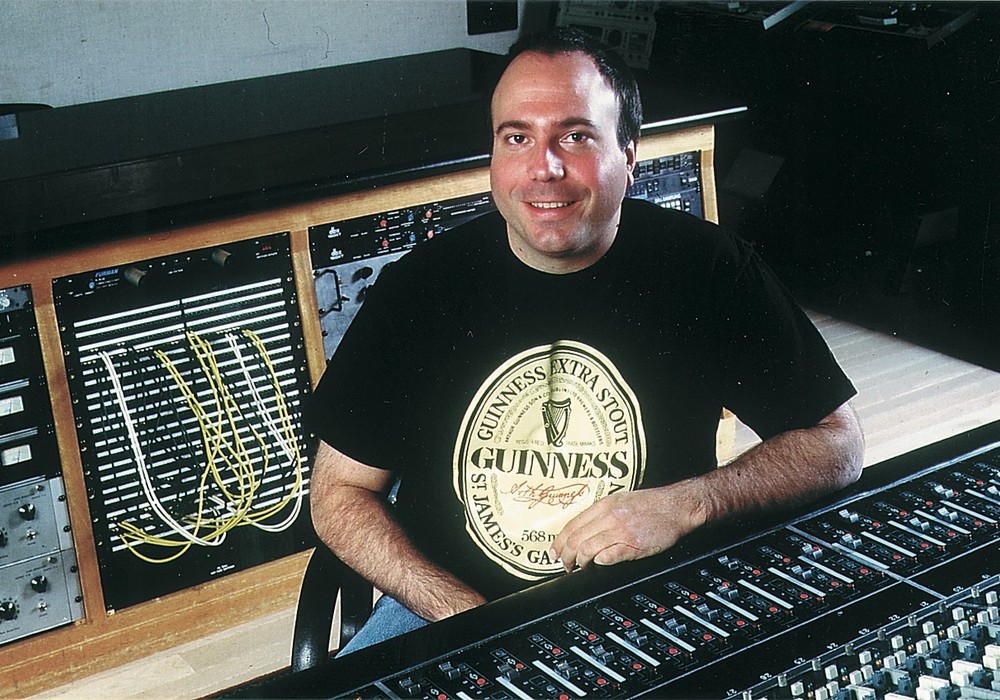

RJ: Yeah. When I left school I went to the shipyard to build nuclear submarines for the Royal Navy. I got engineering training there. My real ambitions were in music. I was a guitar player and I had recording equipment at home, a [Tascam] Portastudio, and I was buying gear. My real passion was to turn my engineering knowledge towards music. I moved down to London when I was 21 and went into a year-long training course in sound engineering. That’s where I met a lecturer, Richard Salter, who was working at Focusrite with the consoles. I had spent a couple of years working freelance in studios. A bit like Phil (at the start of his career), I kind of knew that wasn’t really my long-term goal. I wasn’t really getting enough out of that. Probably because I wasn’t good enough! I said to Richard, because I saw what Focusrite was doing, that I’d like to work there. One day Richard gave me the call, “Come in and help us build this console.”

PD: The first couple of years, Rob had a full-time job installing these consoles around the world.

RJ: Yeah, I spent about three years refining each new version of the console that we made. I refined some extra element. I either worked on the noise floor or the distortion. We really wanted to make the world’s best recording console. We wanted it to have the kind of clarity and quality that the people would complain that the other consoles didn’t deliver anymore. For the next two to three years we were putting consoles into Tokyo and Los Angeles. I would fly off somewhere around the world and spend a few weeks putting consoles in.

Did you do that install at United Recording?

RJ: Yes, it was Ocean Way Recording then. But before that we did Conway [Recording Studios] and later Music Mill [Recording Studios] in Nashville. Three consoles in Tokyo. BearTracks [Recording Studio] in upstate New York. It was a great education, because I hung around with a lot of people who were using gear, as well as learning how to refine audio quality. They say you need 10,000 hours to become an expert at something. Those two years were my 10,000 hours. All we did was eat, sleep, and breathe audio.

How did you guys get from mic pres and EQs that had a lineage with Rupert Neve consoles to doing these incredibly complex and advanced D-to-A and A-to-D converters?

RJ: Well, you take one step at a time. Phil and I aren’t particularly wedded to any audio philosophy, like, “It must be tubes.” There’s no dogma. We’re interested in being relevant to music making. We want to make things that people really use to make music.

PD: I think, initially, we were a bit dogmatic about Rupert Neve’s designs being adhered to, but there was a point in time when we had to make a break with that. The ISA range continues to embody those original Rupert Neve designs to this day. We may have repackaged them, but they’re still essentially the same mic pre, same EQ, etcetera. But Rob was the first person to really suggest the world was changing, and that we needed to change with it. We went through a series of different analog outboard ranges, like the Green Range and the Platinum Range, which were descending in unit cost while still trying to maintain the highest quality at the price point. Then the day came when Rob came up with his first two-channel in-and-out audio interface. At that time we were being distributed by Digidesign in the States. Rob presented his idea to Dave Froker, who was running Digi back then, and he said, “We’ve been thinking about an outboard audio interface like this, but we haven’t got time to do it. What you’re thinking is very consistent with what we want to do.” He sent us a bunch of targets that we would need to achieve, in terms of price point. The main point was he said, “Do it with us, and you’ll sell a lot more of them than if you make a generic sound card/interface.” We negotiated a deal whereby we would design the product that would become the original Mbox, and get it put into production. They would sell it, and we would receive a royalty. That’s what happened, and it was a massive success. We enjoyed really good royalty revenues for many years from that product. We designed a couple of other things: the Control|24 control surface for Pro Tools, and the Command 8, which was smaller control surface. For a period of time we had this really good relationship with Digidesign, where we were designing products that they would then sell alongside Pro Tools. We continued to do our analog products, but the point came when Rob predicted that we might not always be able to enjoy that relationship with Digidesign, which was very farsighted of him. So we started developing our first Sapphire product, which was a two-channel in-and-out FireWire interface. The Whiteface Sapphire, as we call it. We launched that in 2005.

And that lineage continued into the current line?

RJ: That’s right. What’s interesting is the coming of the computer for us was actually a very liberating experience. We were the first company to work with Digidesign on making plug-ins that emulated hardware, the d2 and the d3 [modeled on the Red Range hardware]. The opportunity to work with those guys to create great sounding audio I/O that linked into the computer was something we wanted to push as far as we could go.

PD: We had to develop our capabilities in A-to-D and D-to-A conversion, working initially with USB1 and later on with FireWire and USB2 to provide the connectivity. It didn’t happen overnight. It was a process from the year 2000.

I’d almost forgotten about the Mbox. Now I get it.

RJ: That was a key moment.

PD: The revenue we got from that relationship with Digidesign on the Mbox, as well as other products, has enabled us to invest in more people, as well as build a skill base that has enabled us to be able to build the business we have today. That relationship came to an end around 2006, after they bought M-Audio in 2004. Coincidentally, we bought Novation around the same time. There was a natural divide that took place, and by 2006 we were no longer working together in the way that we had before. Over time the royalties from those past products dwindled away, but by then we’d been able to build our own core competence and our own range of interfaces; the original Sapphire products. By 2008, we had our second generation of Sapphires, which were a lot more reliable than the first ones, improving our chops and design, choosing better components, etcetera. We went into the recession at the end of 2008 with a brand new product range and no debt in the company. That put us in a really strong place to ride out the recession and build our business right through the recession.

RJ: That’s around the time when we began to invest in the next phase, which was audio over IP. We started to invest in developing the components to make the RedNet system. That’s when we sort of raised the bar again, in terms of the audio quality of the converters, but also the idea of creating this modular network system. RedNet is now in its second generation of products. With the Red Interface range that we released last year, without getting into the A-to-D technology, that’s delivering well into the 120 dB dynamic range, and significantly lower EIN [Effective Input Noise] figures, like 129 dB mic noise, which we’re constantly looking for. The combination of silicon and new circuit topologies that push the boundaries of what’s possible in terms of clean audio, low distortion, and wide dynamic range. So if you want to see the combination of 20 odd years of audio design, the RedNet and the Red Interface range really embodies all of those characteristics and values.

_disp_horizontal_bw.jpg)