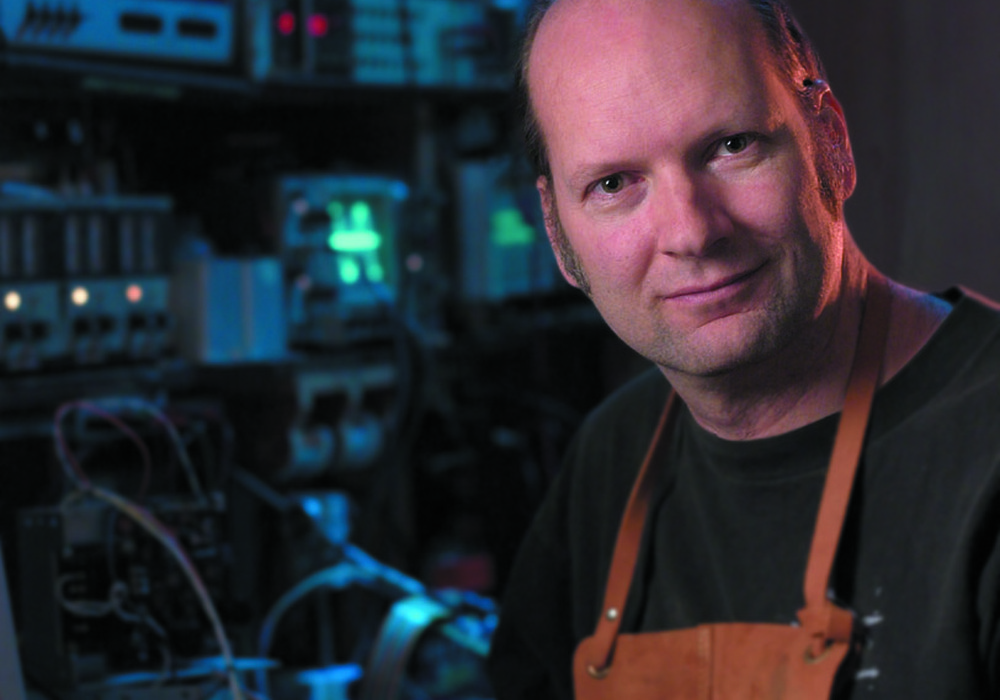

David Josephson, of Josephson Engineering, builds microphones that are innovative, interesting and downright great sounding. We talked about digital audio, cheap mics and the future of microphone design.

How did you get into designing microphones? Do you have a physics or engineering background?

I studied electrical engineering at Berkeley and I was the chief engineer at the radio station on campus for four years and I've always been involved in audio and recordings. I studied physics but I don't consider myself really a physicist, but we're fortunate to have a really expert acoustical engineer on staff now [Kelly Kay] who's part owner of the company. The key is, and this is where some of the traditional microphone companies fall down, they might have a real good physics understanding like the old German companies, but they don't have a musical understanding and the key in making designs that sound good is to balance between physics and music.

What is the difference between a microphone used as a measurement instrument and one used to record music?

The main problem for anybody is it's real easy to measure sound pressure, and if you're using an omni microphone, that's what you're doing — you're measuring pressure. If you're using a small enough microphone then it doesn't really matter what direction the sound is coming from, it's just a variation in sound pressure and that's easy. What's really hard is to sense the sound coming from one direction and not from another and [to] have it be uniform over a broad range of frequencies. You can make an analogy of a TV antenna that gets signals from one direction and not from another. Well, that's fine, but directional antennas work over a frequency range of maybe two to one, and we're asking microphones to be directional over a frequency range of a thousand to one (twenty to twenty thousand hertz). And so most people are recording in environments where they need to use a directional microphone and they want it to be uniformly directional over a range of frequencies and it's just not easy. It's not possible over a really wide range of frequencies, and when you look at how microphones get to directivity over a range of frequencies there are bunch of different mechanisms. One is working in the lows, one in the mids, and several in the high end that cause the directivity and a lot of people don't have the physics background to figure out how that all works and how physics impacts the perceived sound.

What was the first thing you designed and built?

The company began in 1988 as kind of a joint venture with a small German microphone company, to design some products for them and sell them in the US. And we tried that for a couple of years and they ultimately got out of the business. That company has recently sold off the microphone business to some of its employees and you see it now on the market as MBHO. They're doing their traditional product line, but we started out not manufacturing those microphones. But by 1990 we began to take over the production of first the electronics and then the capsules. We just weren't able to get the quality we wanted and ended up having to do everything ourselves here. So it was a hard learning process, but we started with that as the basis, and by 1990 we were making our own designs.

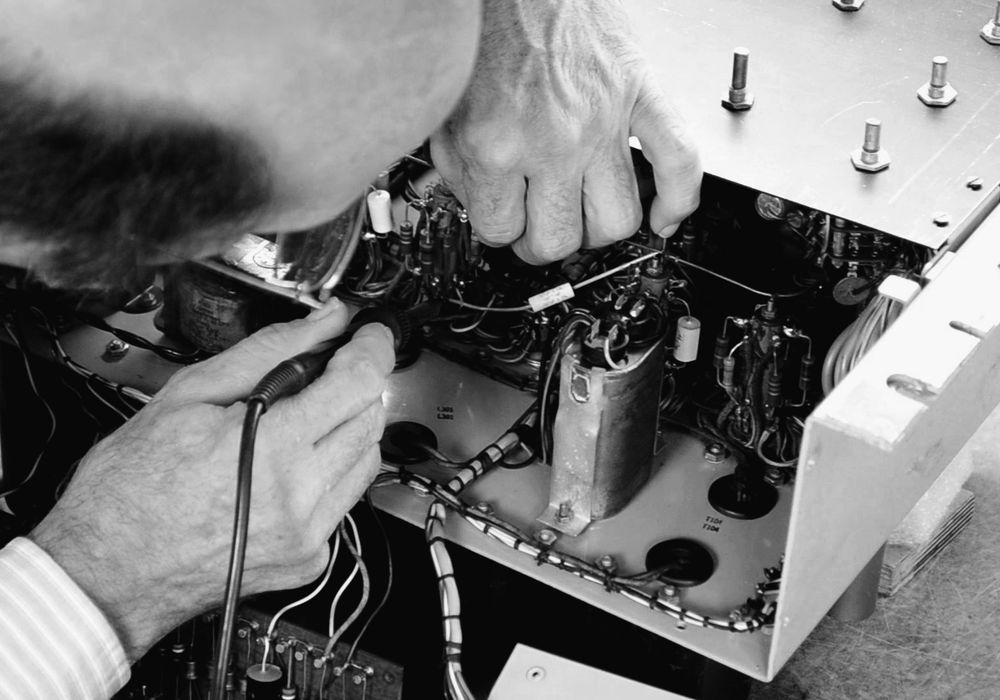

Do you do your own machining?

We started that way. In fact the facility we worked in in San Jose for many years had a lathe and a mill and I made a bunch of parts, not only in our own facility but by me personally, and that was fine as long as I was making pretty much custom — you know, a one man shop-type operation. We began using other far more expert machinists really close by here. They're all Silicon Valley high tech machine shops. We still do a lot of the machining work ourselves, but the majority of the production parts we have other machine shops make.

What more is there to be done in the field of microphone design?

A lot. There's a lot that isn't well understood. And there's a lot we don't...

_disp_horizontal_bw.jpg)