ADK and Marshall Electronics have been selling small- capsule capacitor microphones for the last few years, and I have done a tube modification to a few of them. The performance of the modified microphones is good enough that it seemed reasonable to share this modification. Before discussing the modification, though, I would like to discuss capacitor microphones in general so that their operation will not be a mystery.

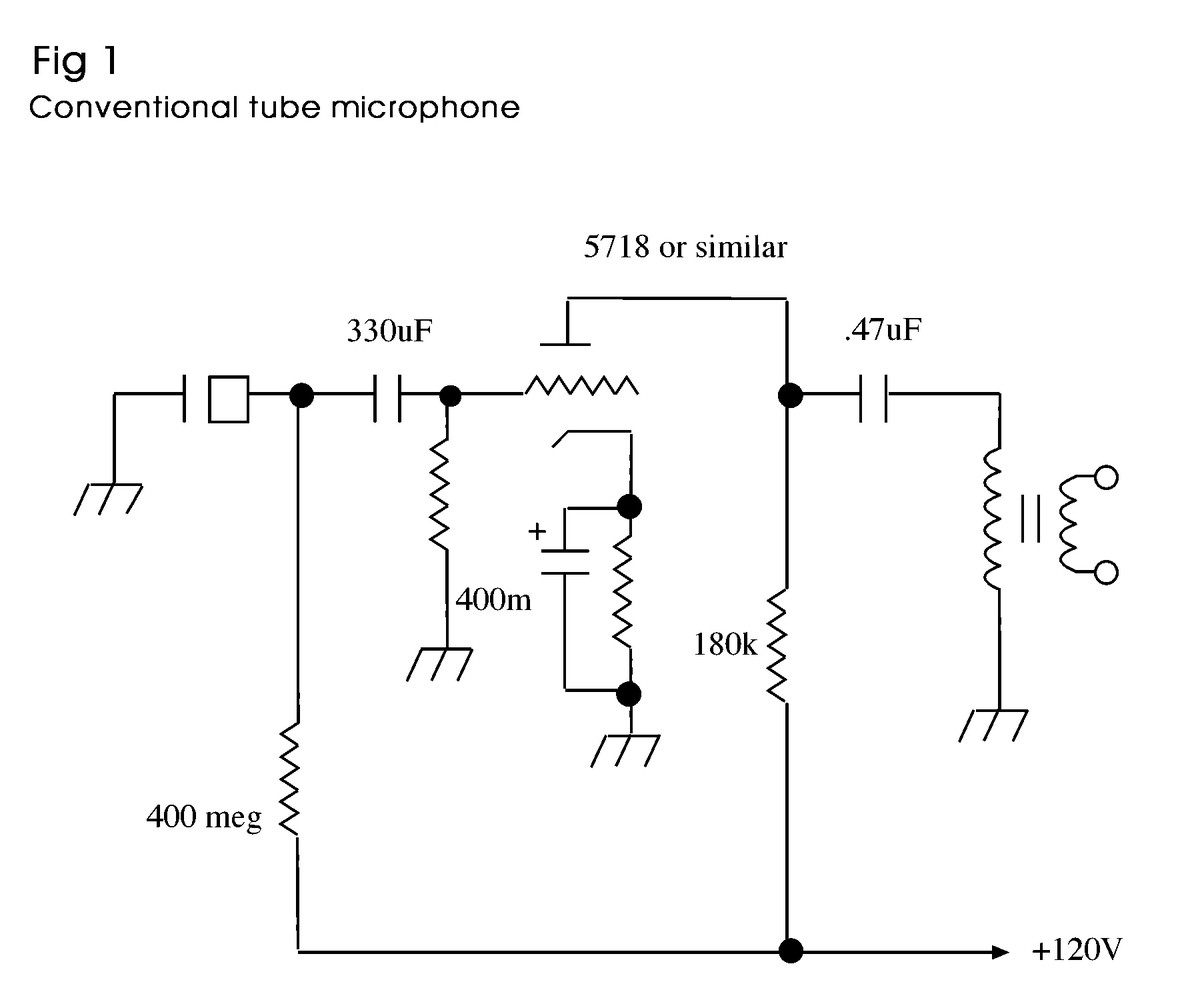

The capsule of a capacitor microphone consists of a very thin diaphragm, made of metallized plastic or a very thin metal foil, which is clamped around its edge under tension so that it can vibrate like a drum head when it is driven by a sound wave. It is spaced perhaps 1/1000 of an inch from a solid metal disc referred to as a backplate. The backplate and the diaphragm are electrically insulated from each other and they form the two plates of a capacitor, the exact capacitance of which will vary as the diaphragm is moved by the influence of a sound wave. With a suitable electrical circuit, the variation of the capacitance can be translated into a corresponding audio signal with excellent frequency response, low noise and low nonlinear distortion. The usual circuit arrangement using a tube is shown in Figure 1.

In this circuit, the diaphragm is grounded and the backplate connects to a fixed DC potential through a resistor of several hundred megaohms. This resistor is a biasing, or polarizing, resistor. The capacitor will charge in a time determined by the RC time constant of the capacitance and the resistance. However, since the capacitance of the microphone capsule is a variable quantity, the voltage across it will vary as the motion of the diaphragm changes the capacitance. The result will be an audio signal at the junction of the microphone's backplate and the polarizing resistor. This signal can then be fed to a vacuum tube (or FET) amplifier, which must be mounted inside the microphone's case. Otherwise, the signal would disappear into thin air due to the extremely high impedance of the circuit.

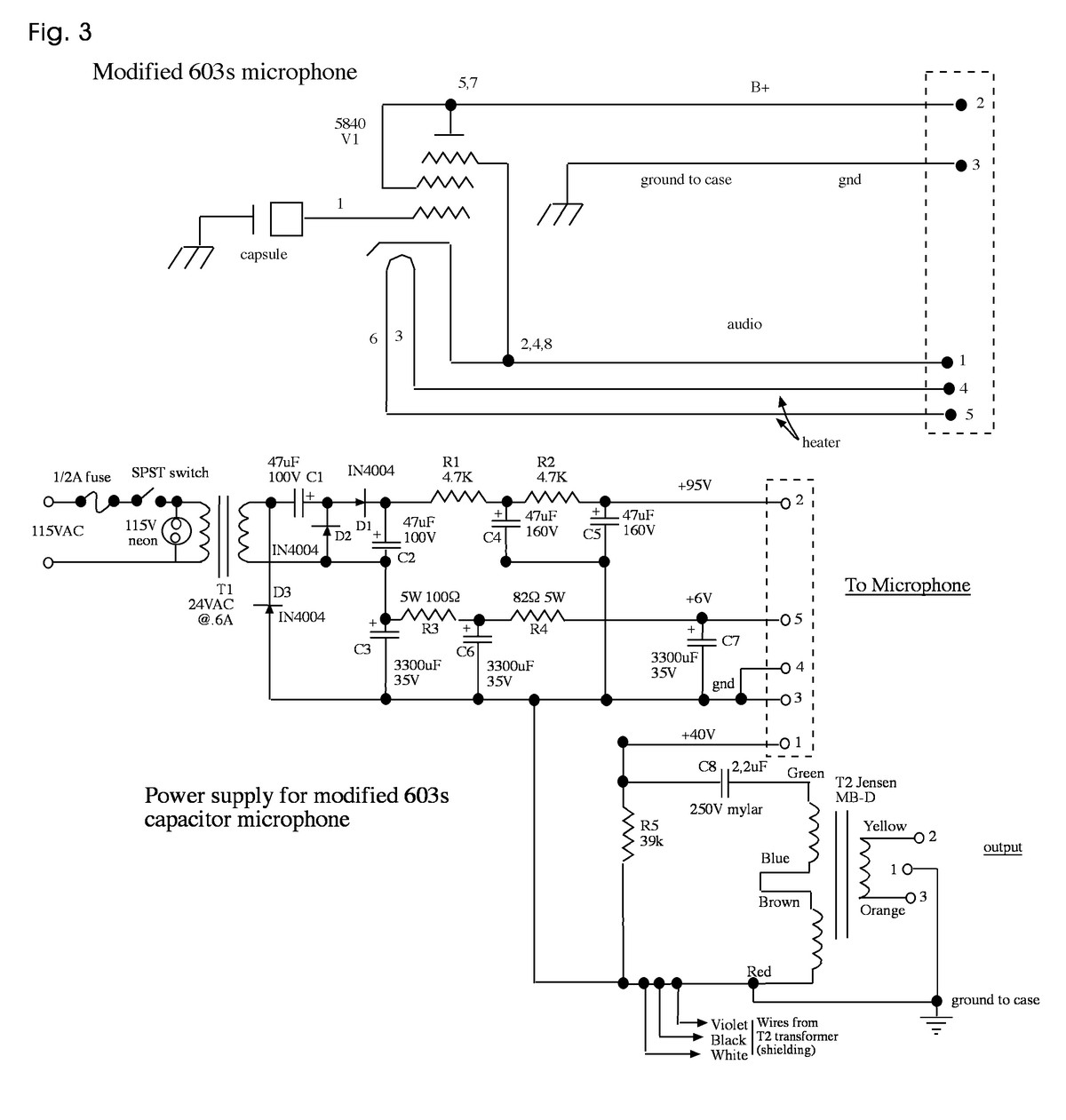

The tube circuit shown here is a generic, "common sense" circuit arrangement, with the capacitors, resistors and output transformer selected to provide low distortion, low noise and flat frequency response. In addition, the output transformer is chosen to provide a standard output impedance of around 200 ohms. Since the microphone capsule and the tube require DC operating voltages, tube microphones were sold with dedicated power supplies, which fed the DC supply voltages to the microphones through special multiple-conductor cables.

Tubes That Stand On Their Heads

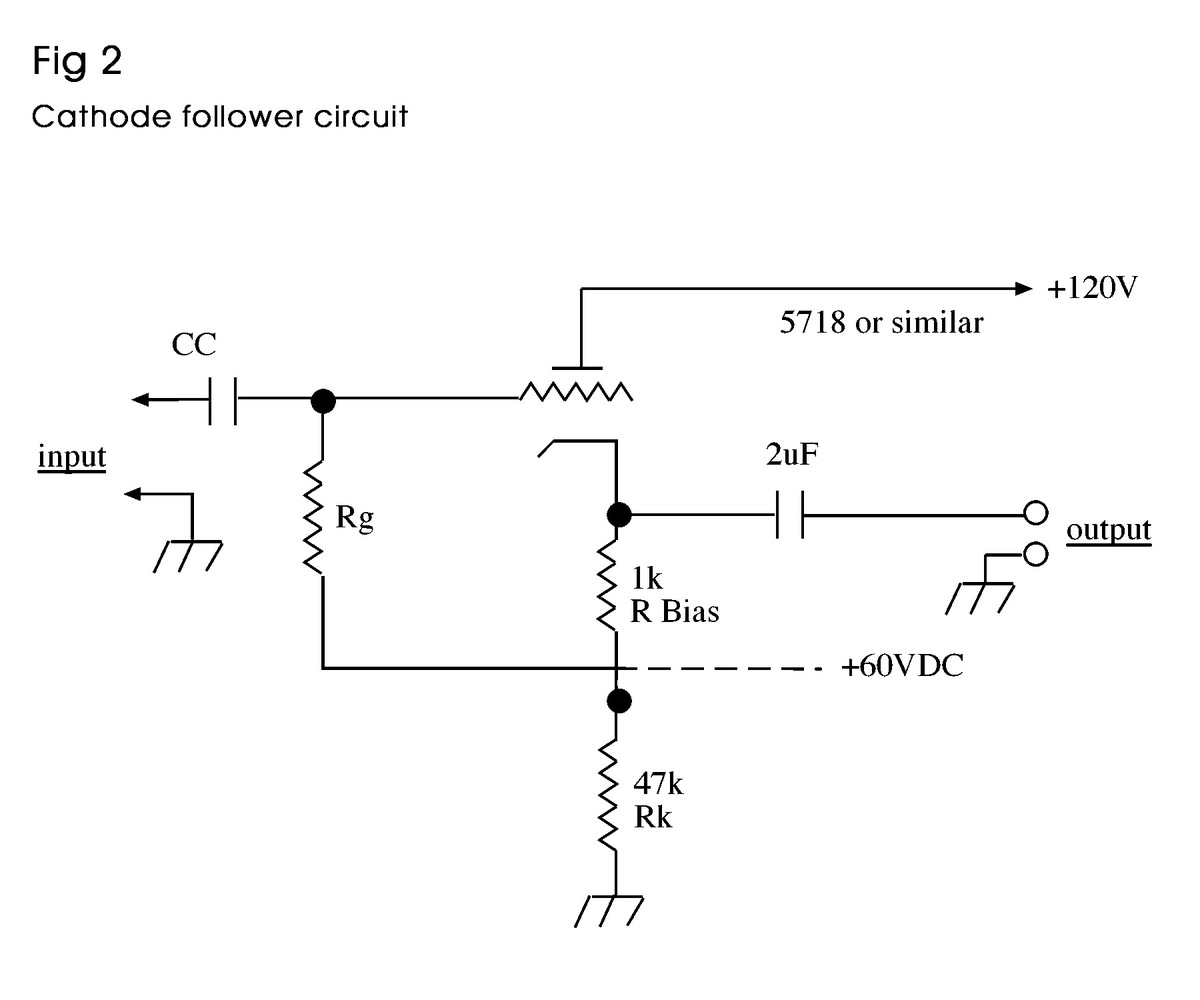

The tube circuit shown in Figure 1 is referred to as a "plate- loaded" circuit. The signal goes in at the grid of the tube and the amplified signal comes out at the plate. Another tube circuit very useful for certain applications is a cathode follower, shown in Figure 2.

With a cathode follower, the signal is put in at the grid and the output is taken off at the cathode of the tube. The cathode resistor is tapped and the grid resistor (Rg) is brought to the tap to set the proper bias point for the tube. Depending on the circuit arrangement, there is often a capacitor in series with the cathode follower's grid to keep the DC potential there from going out into the outside world and causing havoc.

The cathode follower has a low output impedance, typically less than 1000 ohms, which is very useful. In contrast, the same tube in a plate-loaded circuit would have a much higher output impedance, perhaps tens of thousands of ohms. Because of the low output impedance of cathode followers, they were widely used as output buffer stages on preamps, tuners and tape decks, particularly those that were marketed for the home "hi-fi" market. Cathode followers also have very low distortion, low noise and excellent frequency response; they do not "get in the way," sonically. The only drawback to a cathode follower is that it does not have any gain. It just sits there and gives an output signal that is about 9/10 of the input signal, at a low impedance.

Several capacitor microphones have been made using cathode followers rather than plate loaded circuitry, notably the tube amplifier module for the new DPA microphone, as well as the Sony C-37, the Altec tube mics and the AKG C-60 and C-61. Cathode followers were used with all of these microphones, since the output impedance of a cathode follower is low enough to allow the output signal to be fed to a reasonable length of cable without using an audio transformer — very useful for designing a small microphone. Microphones like the AKG C-60 and the Altec had an output transformer in the power supply. Therefore, the cable between the power supply and the following preamp would be balanced and at a standard professional impedance.

The first microphones I built were small capsule mics, about 5/8 inch in diameter and 3 inches long. There was not enough room in the microphone for much of anything besides the tube, so a cathode follower circuit suggested itself. Furthermore, since I was a poor redneck in those days, I wanted to avoid using audio transformers, so cathode followers were my only option, circuit-wise.

A typical way to build a capacitor microphone using a cathode follower is to simply connect the backplate of the microphone capsule to the grid of the cathode follower in Figure 2, omitting the coupling capacitor, and then ground the capsule's diaphragm. The grid resistor Rg is made very large — say, 100 megaohms — and since the "grounded" end of it will "float" at some positive potential, the resistor serves double duty as a grid resistor and as the polarizing resistor for the capsule. To get the desired polarizing voltage for the capsule, you simply tinker the supply voltage and the value of the resistor Rk until you get a reasonable operating point for the tube and a reasonable voltage across Rk, which then becomes the voltage available for polarizing the microphone capsule. For example, in Figure 2, with the circuit constants shown, the voltage across the 47,000-ohm resistor selected for Rk will be around 60 VDC — a perfect polarizing voltage for a typical capacitor mic capsule of modern design with a metallized Mylar diaphragm. In my tube mod to the ADK A-51 SC mics, I am relying on the leakage resistance among the elements of the tube to form Rg and I am using grid leak bias (or contact-potential bias) rather than self- bias. This circuit has been proven to work very satisfactorilly, at least with single-diaphragm mic capsules. (I have found that the circuit needs to be modified to be satisfactory for a double diaphragm multi-pattern capsule, but this issue will have to wait for another time.)

Also, in the tube mod, I have physically located the cathode resistor and the coupling capacitor in the power supply to avoid having a hard-to-assemble mess in the microphone. At first glance, it may seem that the fact that the cathode follower doesn't amplify would rule it out in a capacitor microphone. However, since a plate- loaded circuit requires an output transformer with a high step-down ratio to get the impedance down to 200 ohms or so, the transformer "throws away" most of the tube's gain. With a cathode follower, even with an output transformer selected to give 100 to 200 ohms output impedance, the cathode follower mic would give, at worst, 10 dB less sensitivity than a plate-loaded design with a similar capsule — not bad, particularly when you consider that the cathode follower mic would be all but impossible to overload.

In any case, the cathode follower circuit arrangement seemed "made to order" for the ADK A-51 SC. I revisited it and checked out some audio transformers that seemed likely to provide a balanced, transformer-isolated output, as is standard in the professional world. If you are going to feed unbalanced inputs of medium to high impedance (10,000 ohms or more), the output transformer may be omitted and the signal taken from the cathode follower at the same point where the output transformer primary would connect to the circuit. Do note, though, that the audio signal at the cathode of a cathode follower microphone will be out of phase (the capsule flops the phase), so allowances will need to be made for this. If an output transformer is used, it can be wired to put the phase right. In this article, the output transformer is wired so the signal at the output is the modern standard "pin 2 hot" and the transformer provides an output of around 200 ohms, balanced, in keeping with professional practice.

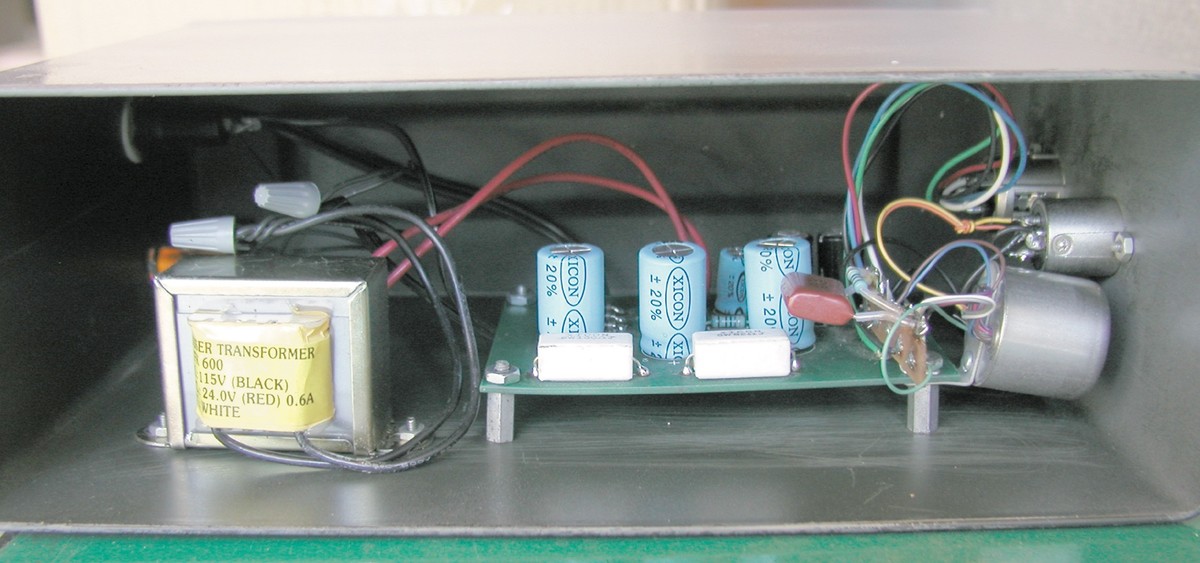

As for the power supply, I am using the same voltage tripler supply as in the earlier Tape Op article ("One Tube Microphone From Berlin And One From Barstow," Sep/Oct 2001). I won't discuss the power supply further, except to mention that it is designed to put out 95 VDC and 6 VDC using a standard 24 VAC power transformer or 24 VAC "wall wart". The wall wart is a handy way to build a power supply without having to worry about going somewhere and being told that you can't plug your something in because it isn't UL-approved. I designed both this power supply and the one for the mod for the 2001 the way I did for this very reason.

Modifying The Microphone

With the ADK A-51 SC mic, the bottom 5/8 inch or so of the mic is fastened to the main part of the housing using three very small screws that turn up from inside the mic (like the screw that holds the insert on a Switchcraft XLR connector) and the capsule (the top 5/8 inch or so of the mic) unscrews from the main part of the housing. A spring-loaded contact in the main part of the housing presses against a contact in the center of the back of the capsule.

To start with the mod, disassemble the microphone, setting the capsule aside in a safe place. When the microphone is disassembled, you will find that there is a long, narrow printed circuit board and a plastic plug at the top of it that carries the spring-loaded contact mentioned above. Wires then lead down from the PCB to the contacts on the XLR connector. You will also find that there are two very small screws that clamp the circuit board to the bottom of the microphone and to the plastic plug, respectively. By loosening the two screws at the bottom and cutting the wires going to the XLR insert, the bottom end of the board can be freed from the microphone's base and the top of the board can be freed by unsoldering the lead going to the spring- loaded contact and loosening the two screws.

Note: The ADK A-51 SC was switchless until 2002, when a 10 dB pad and a bass cut were added (both on one switch). The switch is connected to the mic's circuit board and will come out with the circuit board, but the switch cap, which you see on the outside of the mic, will need to be pried off with a screwdriver before you can remove the mic's electronics. This will leave a hole in the side of the microphone, which will not interfere with the microphones operation.

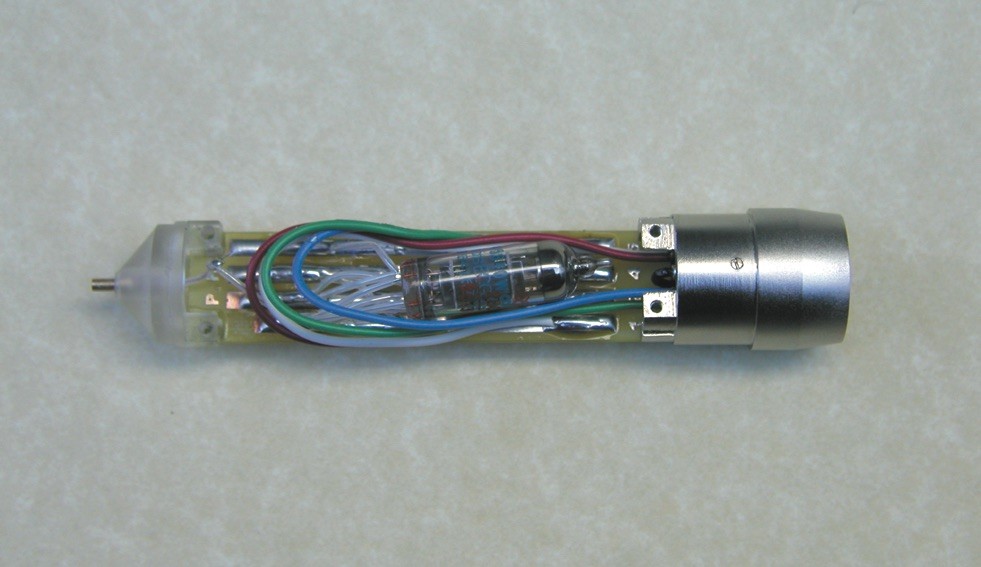

The modification of the microphone is completed by simply replacing the original PCB with another one, laid out for the 5840 tube, and then running the connections from the new PCB down to the prongs on a 5-prong XLR insert that is substituted for the one in the microphone. A PCB is available that is plainly marked at one end for the correct tube elements and at the other with the numbers of the XLR plug prongs, in keeping with the prong assignments shown in Figure 3. Pin 3 of the XLR insert is "jumpered" to the ground lug of the XLR insert.

The tube's leads are soldered to the four traces on the PCB, except for the grid lead, Pin 1. The grid lead must be left its full length to reach to where it connects. The other leads are clipped to a length of about 3/4 of an inch and covered with pieces of Teflon sleeving cut to a length of about 1/2 inch. The tube is mounted so that it will sit upside down in the microphone and the grid lead, covered with a piece of Teflon sleeving, is run to the spring-loaded contact at the top of the microphone.

The power supply for this microphone may be assembled in an ammo box, as recommended in the earlier article, being careful about the polarities of the diodes and capacitors. The power transformer is mounted at the end of the box where the AC cord, switch, fuse and panel lamp are mounted. The output transformer is mounted at the opposite end of the box, adjacent to the 3-prong XLR connector for the main output of the microphone. The 2.2 uF coupling capacitor and the 39k cathode resistor are mounted on a terminal strip mounted next to the output transformer. Note well: Do not use the mounting (center) lug on the terminal strip for any circuit connections.

The 3-prong XLR plug for the output of the microphone is fed from either the cathode follower or from the output transformer secondary. Refer to the diagram in Figure 3 for the correct pin assignments. Remember that the pin numbering of a 3-pin XLR plug defies reason and double- check this. For an unbalanced feed, use Pin 2 as signal "hot" and leave Pin 3 empty.

Upon completion of the microphone, cable and power supply, connect it all together and connect the power supply to the AC power line. The voltages should measure as shown on the diagram in Figure 3. Voltage measures that are radically different indicate a fault. Be aware, though, that the voltage measurements will be radically wrong if the microphone is disconnected.

If you have worked carefully, the modified microphone should work very nicely. I have modified several of them and I have been impressed with the performance, particularly at the price.

I can be reached at ROYERGRIZZ@aol.com, and a kit may be ordered through me. The kit, excluding Jensen MB/D transformer, is available for $170 U.S., including shipping in the United States. This price is subject to change.